A makon da ya gabata, mun gabatar da tsarin naɗewa na capacitors na fim, kuma a wannan makon ina so in yi magana game da babbar fasahar capacitors na fim.

1. Fasaha mai sarrafa tashin hankali akai-akai

Saboda buƙatar ingancin aiki, naɗewa yawanci yana da tsayi mafi girma gabaɗaya a cikin ƙananan microns. Kuma yadda za a tabbatar da cewa matsin lamba na kayan fim ɗin a cikin tsarin naɗewa mai sauri yana da mahimmanci musamman. A cikin tsarin ƙira ba wai kawai muna buƙatar la'akari da daidaiton tsarin injin ba, har ma da cikakken tsarin sarrafa tashin hankali.

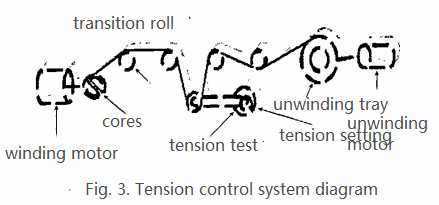

Tsarin sarrafawa gabaɗaya ya ƙunshi sassa da dama: tsarin daidaita tashin hankali, firikwensin gano tashin hankali, injin daidaita tashin hankali, tsarin sauyawa, da sauransu. An nuna zane-zanen tsarin sarrafa tashin hankali a Hoto na 3.

Masu ɗaukar fim suna buƙatar wani matakin tauri bayan naɗewa, kuma hanyar naɗewa ta farko ita ce amfani da bazara a matsayin damping don sarrafa tashin hankalin naɗewa. Wannan hanyar za ta haifar da tashin hankali mara daidaituwa lokacin da injin naɗewa ya yi sauri, ya rage gudu kuma ya tsaya yayin aikin naɗewa, wanda zai sa capacitor ya lalace cikin sauƙi ko ya lalace, kuma asarar capacitor ma yana da yawa. A cikin tsarin naɗewa, ya kamata a kiyaye wani tashin hankali, kuma dabarar ita ce kamar haka.

F=K×B×H

A cikin wannan tsari:F-Tsion

K-Ma'aunin Tesion

B-Faɗin fim (mm)

H-Kauri a fim (μm)

Misali, matsin lambar faɗin fim = 9 mm da kauri fim = 4.8 μm. Jinkirinsa shine: 1.2×9×4.8=0.5(N)

Daga lissafi(1), ana iya samun kewayon tashin hankali. Ana zaɓar maɓuɓɓugar ruwa mai kyau mai layi a matsayin saitin tashin hankali, yayin da ake amfani da potentiometer na induction magnetic wanda ba ya taɓawa a matsayin gano martanin tashin hankali don sarrafa ƙarfin fitarwa da alkiblar motar DC servo mai kwancewa yayin injin lanƙwasa, don haka tashin hankalin ya kasance mai dorewa a duk lokacin aikin lanƙwasa.

2. Fasahar sarrafa na'urori masu juyawa

Ƙarfin ƙwayoyin capacitor yana da alaƙa da adadin juyawar na'urar juyawa, don haka sarrafa madaidaicin ƙwayoyin capacitor ya zama babbar fasaha. Ana yin na'urar juyawar ƙwayar capacitor a babban gudu. Tunda adadin juyawar na'urar juyawa yana shafar ƙimar ƙarfin, sarrafa adadin juyawar na'urar juyawa da ƙidaya yana buƙatar babban daidaito, wanda yawanci ana samunsa ta amfani da na'urar ƙidayar sauri ko firikwensin tare da daidaiton ganowa mai girma. Bugu da ƙari, saboda buƙatar cewa matsin lamba na kayan yana canzawa kaɗan gwargwadon iko yayin aikin na'urar juyawa (in ba haka ba kayan zai yi rawar jiki, yana shafar daidaiton ƙarfin), na'urar juyawa dole ne ta yi amfani da fasahar sarrafawa mai tasiri.

Sarrafa gudu mai rarrabuwa da hanzarta/rage gudu mai ma'ana da sarrafa gudu mai canzawa ɗaya ne daga cikin hanyoyin da suka fi tasiri: ana amfani da saurin juyawa daban-daban don lokutan juyawa daban-daban; a lokacin saurin canzawa, ana amfani da hanzari da raguwa tare da lanƙwasa gudu mai ma'ana don kawar da jitter, da sauransu.

3. Fasahar Rufe Kayayyaki

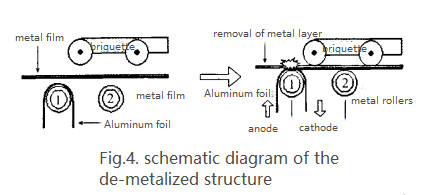

Ana ɗaure abubuwa da yawa a saman juna kuma suna buƙatar maganin rufe zafi a waje da kuma mahadar. Ba tare da ƙara kayan fim ɗin filastik ba, ana amfani da fim ɗin ƙarfe da ke akwai kuma ana amfani da fim ɗin ƙarfensa kuma ana cire murfin ƙarfensa ta hanyar fasahar rage ƙarfe don samun fim ɗin filastik kafin hatimin waje.

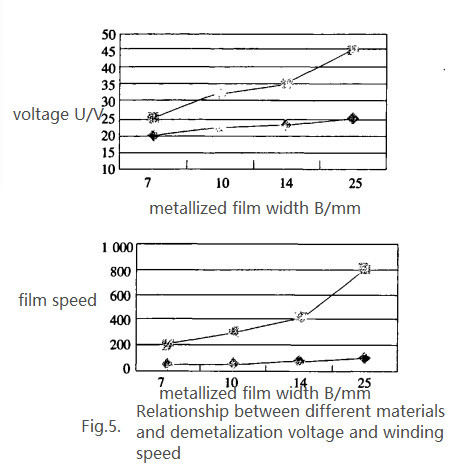

Wannan fasaha na iya adana kuɗi mai yawa kuma a lokaci guda rage diamita na waje na core capacitor (idan akwai ƙarfin daidai na core). Bugu da ƙari, ta amfani da fasahar demetalization, ana iya cire murfin ƙarfe na wani Layer (ko layuka biyu) na fim ɗin ƙarfe a gaba a mahaɗin tsakiya, don haka guje wa faruwar gajeriyar da'ira, wanda zai iya inganta yawan ƙwayoyin da aka naɗe sosai. Daga Hoto na 5, za a iya kammala da cewa don cimma irin wannan tasirin cirewa. An tsara ƙarfin cirewa don daidaitawa daga 0V zuwa 35V. Dole ne a rage saurin zuwa tsakanin 200r/min da 800 r/min don demetalization bayan naɗewar sauri mai girma. Ana iya saita ƙarfin lantarki da sauri daban-daban don samfura daban-daban.

4. Fasahar rufe zafi

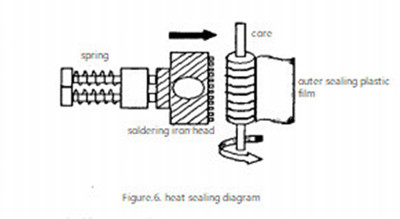

Hatimin zafi yana ɗaya daga cikin manyan fasahohin da ke shafar cancantar ƙwayoyin capacitor na rauni. Hatimin zafi shine amfani da ƙarfe mai zafi don ɗaure da haɗa fim ɗin filastik a mahaɗin ƙwayar capacitor mai naɗewa kamar yadda aka nuna a Hoto na 6. Don kada a naɗe tsakiyar, ana buƙatar a haɗa shi da aminci kuma fuskar ƙarshe ta yi faɗi kuma kyakkyawa. Manyan abubuwa da yawa da ke shafar tasirin hatimin zafi sune zafin jiki, lokacin hatimin zafi, birgima ta tsakiya da saurin gudu, da sauransu.

Gabaɗaya, zafin rufewar zafi yana canzawa tare da kauri na fim ɗin da kayan. Idan kauri na fim ɗin kayan iri ɗaya shine 3μm, zafin rufewar zafi yana cikin kewayon 280℃ da 350℃, yayin da kauri na fim ɗin shine 5.4μm, ya kamata a daidaita zafin rufewar zafi zuwa kewayon 300cc da 380cc. Zurfin rufewar zafi yana da alaƙa kai tsaye da lokacin rufewar zafi, matakin crimping, zafin ƙarfe na soldering, da sauransu. Ƙwarewar zurfin rufewar zafi kuma yana da mahimmanci musamman don ko za a iya samar da ƙwallan capacitor masu cancanta.

5. Kammalawa

Ta hanyar bincike da haɓakawa a cikin 'yan shekarun nan, masana'antun kayan aiki da yawa na cikin gida sun ƙirƙiri kayan aikin juyawa na capacitor na fim. Da yawa daga cikinsu sun fi samfuran iri ɗaya a gida da waje dangane da kauri na kayan aiki, saurin juyawa, aikin cire ƙarfe da kewayon samfuran juyawa, kuma suna da matakin fasaha na zamani na duniya. Ga taƙaitaccen bayani game da babbar fasahar fasahar juyawa na capacitor na fim, kuma muna fatan cewa tare da ci gaba da ci gaban fasahar da ke da alaƙa da tsarin samar da capacitor na fim na cikin gida, za mu iya haɓaka masana'antar kayan aikin kera capacitor na fim a China.

Lokacin Saƙo: Maris-15-2022