A makon da ya gabata, mun gabatar da tsarin winding na fim capacitors, kuma a wannan makon zan so in yi magana game da mahimmin fasahar fasahar fina-finai.

1. Fasaha kula da tashin hankali akai-akai

Saboda buƙatar ingantaccen aiki, iska yawanci yana kan tsayi mafi girma gabaɗaya a cikin 'yan microns.Kuma yadda za a tabbatar da tashin hankali na kayan fim na yau da kullum a cikin tsarin iska mai sauri yana da mahimmanci.A cikin tsarin ƙira ba kawai muyi la'akari da daidaiton tsarin injiniya ba, amma kuma muna da cikakkiyar tsarin kula da tashin hankali.

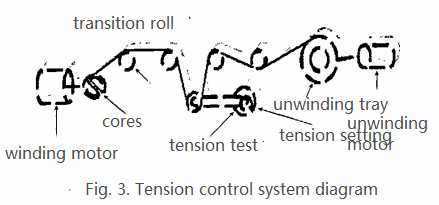

Tsarin sarrafawa gabaɗaya ya ƙunshi sassa da yawa: injin daidaita tashin hankali, firikwensin gano tashin hankali, daidaita motsin motsi, tsarin canji, da sauransu. An nuna zane-zane na tsarin sarrafa tashin hankali a cikin siffa 3.

Fim capacitors na bukatar wani mataki na taurin bayan iska, da kuma farkon winding hanyar ne a yi amfani da bazara a matsayin damping don sarrafa iska tashin hankali.Wannan hanya za ta haifar da tashin hankali mara daidaituwa a lokacin da motar da ke motsawa ta hanzari, raguwa da tsayawa yayin aikin na'urar, wanda zai sa capacitor ya zama mai sauƙi ko lalacewa, kuma asarar capacitor yana da yawa.A cikin tsarin iska, ya kamata a kiyaye wani tashin hankali, kuma tsarin shine kamar haka.

F=K×B×H

A cikin wannan tsari:F-Tesion

K-Tesion coefficient

B- Nisa fim (mm)

H-Kaurin fim (μm)

Misali, tashin hankali na fadin fim = 9 mm da kauri na fim = 4.8μm.Tashin hankali shine: 1.2×9×4.8=0.5(N)

Daga lissafin (1), ana iya samun kewayon tashin hankali.An zaɓi maɓuɓɓugar ruwa mai kyau tare da layi mai kyau azaman saitin tashin hankali, yayin da ake amfani da potentiometer induction na maganadisu mara lamba azaman ganowar amsawar tashin hankali don sarrafa juzu'in fitarwa da jagorar injin DC servo mai buɗewa yayin injin iska, don tashin hankali. shi ne akai-akai a ko'ina cikin iska.

2. fasahar sarrafa iska

Ƙarfin muryoyin capacitor yana da alaƙa da kusanci da adadin jujjuyawar iska, don haka daidaitaccen sarrafa muryoyin capacitor ya zama fasaha mai mahimmanci.Ana yin iskar capacitor core akan babban gudu.Tun da yawan jujjuyawar juyawa kai tsaye yana shafar ƙimar ƙarfin aiki, sarrafa adadin jujjuyawar juyawa da ƙidayar yana buƙatar daidaito mai girma, wanda galibi ana samun ta ta amfani da babban ƙidayar ƙidayar sauri ko firikwensin tare da babban ganowa.Bugu da ƙari, saboda abin da ake buƙata cewa tashin hankali na kayan yana canzawa kadan kamar yadda zai yiwu a yayin aikin motsa jiki (in ba haka ba kayan zai zama babu makawa, yana shafar daidaiton iya aiki), dole ne iska ta yi amfani da fasahar sarrafawa mai tasiri.

Rarraba sarrafa saurin gudu da madaidaicin hanzari / ragewa da sarrafa saurin saurin canzawa shine ɗayan ingantattun hanyoyin: ana amfani da saurin iska daban-daban don lokuta daban-daban;a lokacin lokacin saurin canzawa, ana amfani da hanzari da raguwa tare da madaidaicin madaidaicin madaidaicin saurin don kawar da jitter, da dai sauransu.

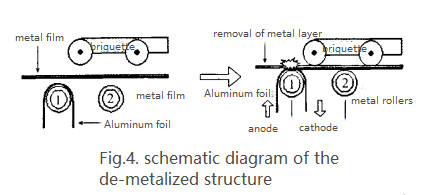

3. Fasahar Demetallization

Yadudduka da yawa na kayan suna rauni a saman juna kuma suna buƙatar maganin rufewar zafi a waje da dubawa.Ba tare da ƙara kayan fim ɗin filastik ba, ana amfani da fim ɗin ƙarfe da ake amfani da shi kuma ana amfani da fim ɗin ƙarfensa kuma ana cire platin ƙarfensa ta hanyar fasahar de-metalization don samun fim ɗin filastik kafin hatimin waje.

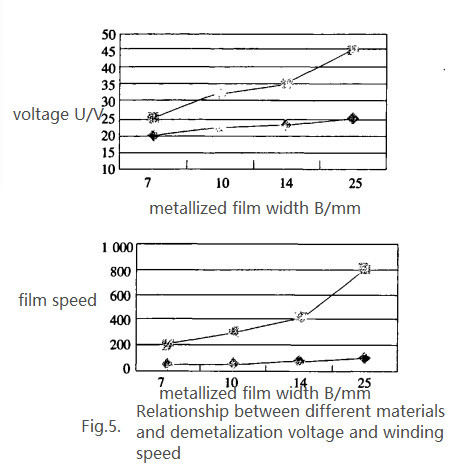

Wannan fasaha na iya adana farashin kayan abu kuma a lokaci guda rage diamita na waje na core capacitor (a cikin yanayin daidai ƙarfin ainihin).Bugu da ƙari, ta hanyar yin amfani da fasaha na lalata, za a iya cire murfin karfe na wani Layer (ko biyu yadudduka) na fim ɗin ƙarfe a gaba a babban haɗin gwiwa, don haka guje wa faruwar wani ɗan gajeren da'ira, wanda zai iya inganta yawan amfanin ƙasa. na murƙushe murhu.Daga Figure.5, ana iya ƙaddamar da cewa don cimma sakamako iri ɗaya.An tsara ƙarfin cirewa don daidaitawa daga 0V zuwa 35V.Dole ne a rage gudun zuwa tsakanin 200r/min da 800 r/min don lalatawa bayan babban iskar gudu.Za'a iya saita wutar lantarki daban-daban da sauri don samfuran daban-daban.

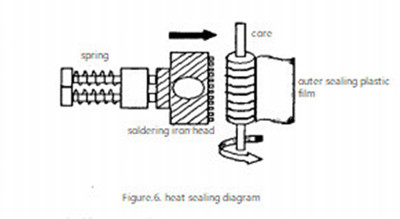

4. fasahar rufe zafi

Rufe zafi yana ɗaya daga cikin mahimman fasahohin da ke shafar cancantar ma'aunin ƙarfin rauni.Rufewar zafi shine a yi amfani da ƙarfe mai girman zafin jiki don murƙushewa da ɗaure fim ɗin filastik a mahaɗin naɗaɗɗen capacitor core kamar yadda aka nuna a Figure.6.Don kada a yi birgima a hankali, ana buƙatar a haɗa shi da aminci kuma fuskar ƙarshen tana da faɗi da kyau.Yawancin manyan abubuwan da ke shafar tasirin hatimin zafi sune zafin jiki, lokacin rufe zafi, core yi da sauri, da sauransu.

Gabaɗaya magana, yanayin zafi na rufewar zafi yana canzawa tare da kauri na fim da kayan.Idan kauri daga cikin fim na wannan abu ne 3μm, da yawan zafin jiki na zafi sealing ne a cikin kewayon 280 ℃ da 350 ℃, yayin da kauri na fim ne 5.4μm, da yawan zafin jiki na zafi sealing ya kamata a daidaita zuwa kewayon 300cc da 380cc.Zurfin zafi sealing ne kai tsaye alaka da zafi sealing lokaci, crimping digiri, soldering baƙin ƙarfe zafin jiki, da dai sauransu The mastering na zafi sealing zurfin ne ma da muhimmanci musamman ga ko m capacitor tsakiya za a iya samar.

5. Kammalawa

Ta hanyar bincike da haɓakawa a cikin 'yan shekarun nan, masana'antun kayan aikin gida da yawa sun haɓaka kayan aikin iska na fim.Yawancin su sun fi samfuran iri ɗaya a gida da waje dangane da kauri na kayan abu, saurin iska, aikin lalatawa da kewayon samfura, kuma suna da matakin fasahar ci gaba na duniya.Anan akwai taƙaitaccen bayanin mahimmin fasahar fasahar sarrafa fina-finai ta iska, kuma muna fatan cewa, tare da ci gaba da ci gaban fasahar da ta shafi aikin samar da na'urar samar da fina-finai ta cikin gida, za mu iya ba da himma wajen haɓaka masana'antar kera kayan aikin fim a kasar Sin. .

Lokacin aikawa: Maris 15-2022